| Brief introductionY11 series Y11 series | top ↑ |

Y11 series Y11 series The Y11 series small circular electric connector is suitable for the strategic and tactic armament system, astronautics satellite system, the aviation navigation transport, the earth launching and receiving system, the high energy high fever industrial system, the communication and test system, the current system of transport and so on the electrical signal connection. This type product has merits such as quick coupling and quick abruption, small volume, and lightweight receptacle with coupling by inlet bayonet locking. The contact is weld. The shell includes shielding and non-shielding type, it also has normal sealed, high vacuum-sealed, high-pressure sealed and rain and dust defending function. The seal type of the receptacle has glue poured and glass fusion, and its mounting styles have flange, nut fixed and wall crossed types and so on. |

Y11 series Y11 series |

| specificationY11 series Y11 series | top ↑ |

Y11 series Y11 series Contacts Characteristics

Pin-diameter(mm) | 1 | 1.5 | Working current(A) | 5 | 10 | Materials | Copper Alloy | Iron alloy | Copper Alloy | Iron alloy | Contact resistance(mO) | =5 | =15 | =3 | =10 |

Insulated resistance

Standard air pressure | Humidity | Raining | High temperature conditions | =3000MO | =20MO | =20MO | =500MO |

Voltage resistance

Standard air pressure | AC 1500Vrms | Lower air pressure | AC 200Vrms | Humid conditions | AC 500Vrms |

Electric continuity between Shells-- Not more than 0.2O

Electric continuity between shielding Shells -- Not more than 0.005O When electromagnetic interference 800MHz, the minimum attenuation is 45dB Sealing : glue Receptacle 02Mpa Glass fusion Receptacle Not more than 1×10-5Pal/s Mechanical life-span 500 |

Y11 series Y11 series |

| how to orderY11 series Y11 series | top ↑ |

Y11 series Y11 series Model signs Y 11 X ? - 20 41 Z J 10 - 2

? ? ? ? ? ? ? ? ? ? Implementation of the standards

Q/321283LSB03-2004 ?Circular Connector

? design NO.

? categories : X-rubber seal, H- glass fusion (receptacle), P- shielding glue seal, S-copper shell glue seal

? dislocation NO. : I, II, III, IV, V, No. 1 no Tagging

? Shell NO. : 08,10,12,14,1, 6,18,20,22,24

? Q’ty of conta, , , , , , ct : 4,7,10,1, 2,16,19,21,26,32,41,55,61

? Connector categories : T-Plug, Z- receptacle

? Contacts type : J-pin, K-jack

? mounting styles : 10-square flange, 11-round flange, 14-nut fixed

? cable coat forms : 2-jiaxianban, 5- heat shrink type 1,

5a- heat shrink type 2, 6-shielding |

Y11 series Y11 series |

| Product InformationY11 series Y11 series | top ↑ |

Y11 series Y11 series Users may need to function in accordance with orders, production side by the functional needs of users Availability assembly, to achieve reasonable economic use. Special orders must refer to the following special structural components, according to code components for orders. Component code is Y11 - × × 00-80, Y11 - × × 00-81, Y11 - × × 00, -83, Y11 - × × 00-84, Y11 - × × 00-85, Y11 - × × 00-86 , Y11,,, - x 00-87, Y11 - × × 00-88, Y11 - × × 00-89. Middle markers "x 00", it said, the shell can be arbitrarily selected. For instance, on the 14th set of plug metal shell oven, in order to write single residues, -1400-80; To set on the 10th metal socket shell oven, then write Y11-1000-81; To set on the 18th empty shell socket, write Y11-1800-83. Y11S series of copper cable enclosures required separate orders, codenamed Y11 - × × 00-93, structural forms and dimensions and Y11-the same × × 00-88, with a total length of 15mm. |

Y11 series Y11 series |

| AccessoriesY11 series Y11 series | top ↑ |

Y11 series Y11 series Metal Shield plug cover(Y11-××00-80) Metal Shield receptacle cover(Y11-××00-81) | Empty receptacle(Y11-××00-83) | Open-long cable coat(Y11-××00-85) | Shell NO. | A | L1 | L2 | B | M | 08 | f17 | 15 | 29 | 2.5 | M14×1 | 10 | f20 | 15 | 29 | 2.5 | M18×1 | 12 | f24.5 | 15 | 31 | 2.5 | M20×1 | 14 | f26.5 | 20 | 38 | 3 | M24×1 | 16 | f29.5 | 20 | 39 | 3 | M27×1 | 18 | f32.5 | 20 | 40 | 4 | M30×1 | 20 | f35.5 | 22 | 42 | 4.5 | M33×1.5 | 22 | f38.5 | 22 | 42 | 5 | M36×1.5 | 24 | f41.5 | 27 | 47 | 5 | M39×1.5 | Shielded cables coat(Y11-××00-86) | Shell NO. | L | H | f | 08 | 35 | f10 | 18 | 10 | 35 | f10 | 21 | 12 | 37 | f14.5 | 25.5 | 14 | 40 | f16.5 | 29 | 16 | 40 | f16.5 | 31 | 18 | 50 | f20 | 34 | 20 | 50 | f22.5 | 39 | 22 | 50 | f22.5 | 38.5 | 24 | 50 | f24 | 41.5 | Long cable coat(Y11-××00-88) | Shell NO. | A | B | E | D | M | L1 | L2 | 08 | f14 | f6 | f13 | f17 | M14×1 | 29 | 35 | 10 | f17 | f8 | f16 | f20 | M18×1 | 29 | 35 | 12 | f20 | f10 | f19 | f26.5 | M20×1 | 30 | 37 | 14 | f24 | f12 | f23 | f22.5 | M24×1 | 34 | 43 | 16 | f26 | f14 | f25 | f29.5 | M27×1 | 34 | 43 | 18 | f30 | f17 | f29 | f32.5 | M30×1 | 34 | 43 | 20 | f33 | f20 | f31 | f35.5 | M33×1.5 | 36 | 45 | 22 | f36 | f24 | f34 | f38.5 | M36×1.5 | 36 | 45 | 24 | f39 | f27 | f37 | f41.5 | M39×1.5 | 41 | 50 | Heat shrink type 1 cable coat(Y11-××00-84) | Shell NO. | fA | fB | fC | fD | M | L1 | L2 | 08 | 20 | 9 | 11 | 13 | M14×1 | 27 | 15 | 10 | 24 | 10 | 12 | 14 | M18×1 | 27 | 15 | 12 | 26.5 | 13 | 15 | 17 | M20×1 | 30 | 15 | 14 | 30.5 | 17 | 19 | 21 | M24×1 | 31 | 16 | 16 | 33 | 18 | 20 | 22 | M27×1 | 31 | 18 | 18 | 36 | 23 | 25 | 27 | M30×1 | 34 | 22 | 20 | 39.8 | 24 | 26 | 28 | M33×1.5 | 35 | 20 | 22 | 42 | 27 | 29 | 31 | M36×1.5 | 34 | 22 | 24 | 45 | 30 | 32 | 34 | M39×1.5 | 36 | 24 | Heat shrink type 2 cable coat(Y11-××00-89) | Shell NO. | fA | fB | fC | fD | M | L1 | L2 | 08 | 20 | 8.7 | 12.8 | 14.8 | M14×1 | 33 | 20 | 10 | 24 | 10 | 14.4 | 16.4 | M18×1 | 33 | 20 | 12 | 26.5 | 15 | 19.1 | 21.1 | M20×1 | 33 | 20 | 14 | 30.5 | 18.2 | 22.3 | 24.3 | M24×1 | 33 | 20 | 16 | 33 | 18.2 | 22.3 | 25.3 | M27×1 | 33 | 20 | 18 | 36 | 24.5 | 28.7 | 30.7 | M30×1 | 33 | 20 | 20 | 39.8 | 24.5 | 28.7 | 30.7 | M33×1.5 | 35 | 20 | 22 | 42 | 27.7 | 31.8 | 33.8 | M36×1.5 | 35 | 20 | 24 | 45 | 30 | 31.8 | 34 | M39×1.5 | 35 | 20 | Y11 insulation installation location transform plate | Marker code | ? | ? | ? | ? | ? | Keyway installation of five letters | I | L | T | V | Y | And the main point of the Key | 0° | 100° | 150° | 155° | 95° | Y11 Contacts Kong-listed

Note : This map -- the connector inserted a pin-View? |

Y11 series Y11 series |

| Environmental ConditionY11 series Y11 series | top ↑ |

Y11 series Y11 series Relative Temperature | -55? ~ +125? | Relative Humidity | when40 ± 2?, up to 95% ± 95% | Operating Pressure | 101.33kPa ~ 4.39kPa | Sin Vibration | vibration frequency 10Hz ~ 2000HZ, acceleration 196m/s2 | Random Vibration | Power spectral density of 40m2/s4Hz,the root-mean-square of 239.1m/s2 | Impact | acceleration 980.7m/s2 | Rain Resistance | rainfall 5mm/min | Salt Spray | By GJB101A-97 implementation, 3.6.13 |

|

| Outline Mounting DimensionsY11 series Y11 series | top ↑ |

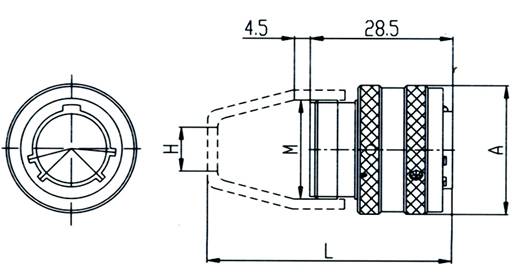

Y11 series Y11 series Plug a

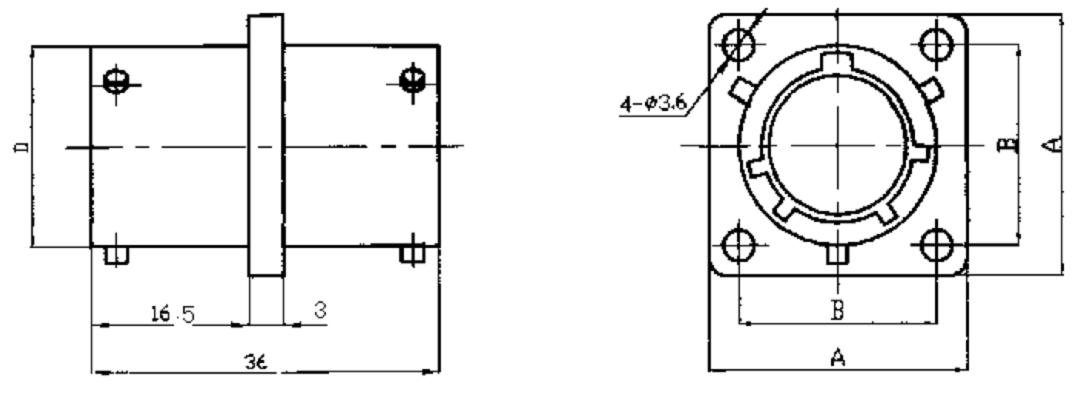

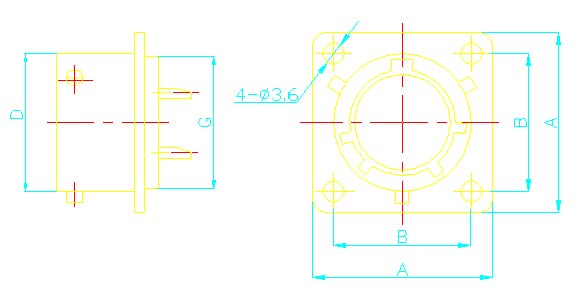

| Shell NO. | A | M | H | L | 08 | f20 .5 | M14×1 | f6 | 41 | 10 | f23 | M18×1 | f8 | 41 | 12 | f26 | M20×1 | f10 | 43 | 14 | f30 | M24×1 | f12 | 49 | 16 | f33 | M27×1 | f14 | 49 | 18 | f36 | M30×1 | f17 | 49 | 20 | f39 | M33×1.5 | f20 | 50.5 | 22 | f42 | M36×1.5 | f24 | 50.5 | 24 | f45 | M39×1.5 | f27 | 55 | Square flange receptacle | Shell NO. | A | B | D | E | M | H | L | 08 | 21 | 15±0.15 | f13 | 1.5 | M14×1 | f6 | 41.5 | 10 | 24 | 18±0.15 | f16 | 1.5 | M18×1 | f8 | 41.5 | 12 | 27 | 21±0.15 | f20 | 1.5 | M20×1 | f10 | 43.5 | 14 | 30 | 23±0.15 | f23 | 1.5 | M24×1 | f12 | 49.5 | 16 | 33 | 25±0.15 | f26 | 1.5 | M27×1 | f14 | 49.5 | 18 | 36 | 27±0.15 | f29 | 1.5 | M30×1 | f17 | 49.5 | 20 | 39 | 29±0.15 | f32 | 2.2 | M33×1.5 | f20 | 51 | 22 | 42 | 32±0.15 | f35 | 2.2 | M36×1.5 | f24 | 51 | 24 | 45 | 35±0.15 | f38 | 2.2 | M39×1.5 | f27 | 55 | Square flange wall cut through receptacle

| Shell NO. | A | B | D | 08 | 21 | 15±0.15 | f13 | 10 | 24 | 18±0.15 | f16 | 12 | 27 | 21±0.15 | f20 | 14 | 30 | 23±0.15 | f23 | 16 | 33 | 25±0.15 | f26 | 18 | 36 | 27±0.15 | f29 | 20 | 39 | 29±0.15 | f32 | 22 | 42 | 32±0.15 | f35 | 24 | 45 | 35±0.15 | f38 | Nut fixed socket receptacle

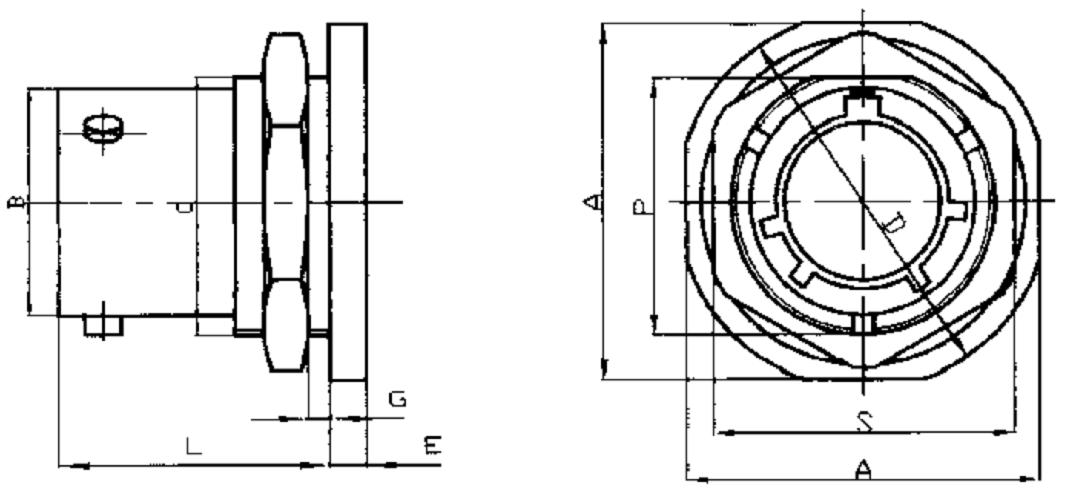

| Shell NO. | G | E | L | B | C | A | D | P | S | min | max | 08 | 1.6 | 3.2 | 2.5 | 18.5 | f13 | M16×1 | 24 | f27 | 15 | 22 | 10 | 1.6 | 3.2 | 2.5 | 18.5 | f16 | M20×1 | 27 | f30 | 19 | 24 | 12 | 1.6 | 3.2 | 2.5 | 18.5 | f20 | M24×1 | 32 | f35 | 23 | 27 | 14 | 1.6 | 3.2 | 2.5 | 18.5 | f23 | M27×1 | 36 | f38 | 26 | 30 | 16 | 1.6 | 3.2 | 2.5 | 18.5 | f26 | M30×1 | 38 | f42 | 29 | 32 | 18 | 1.6 | 3.2 | 2.5 | 18.5 | f29 | M33×1.5 | 41 | f45 | 32 | 36 | 20 | 1.6 | 6.4 | 3.0 | 22.5 | f32 | M36×1.5 | 46 | f49 | 35 | 41 | 22 | 1.6 | 6.4 | 3.0 | 22.5 | f35 | M39×1.5 | 50 | f53 | 38 | 43 | 24 | 1.6 | 6.4 | 3.0 | 22.5 | f38 | M42×1.5 | 53 | f56 | 41 | 46 | Square flange glass fusion receptacle

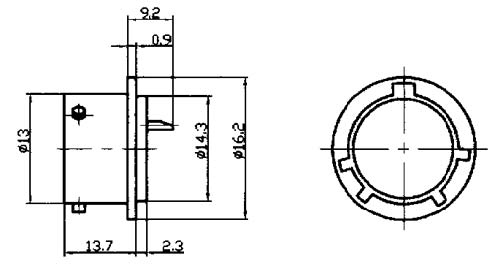

| Shell NO. | A | B | D | G | 08 | 21 | 15±0.15 | f13 | f12 | 10 | 24 | 18±0.15 | f16 | f16 | 12 | 27 | 21±0.15 | f20 | f19 | 14 | 30 | 23±0.15 | f23 | f22 | 16 | 33 | 25±0.15 | f26 | f25 | 18 | 36 | 27±0.15 | f29 | f28 | 20 | 39 | 29±0.15 | f32 | f31 | 22 | 42 | 32±0.15 | f35 | f34 | 24 | 45 | 35±0.15 | f38 | f37 | Y11H-0804ZJ11circular flange glass fusion receptacle

|

Y11 series Y11 series |

|